Day 1 :

Keynote Forum

Bernard Pelissier

CNRS, LTM, MINATEC Campus, France

Keynote: Quasi in situ XPS characterization applied to PEALD selective deposition of TiO2 the IMPACT 300mm project and platform: Merging academic research and industrial applications in microelectronic

Time : 10:05-10:40

Biography:

Abstract:

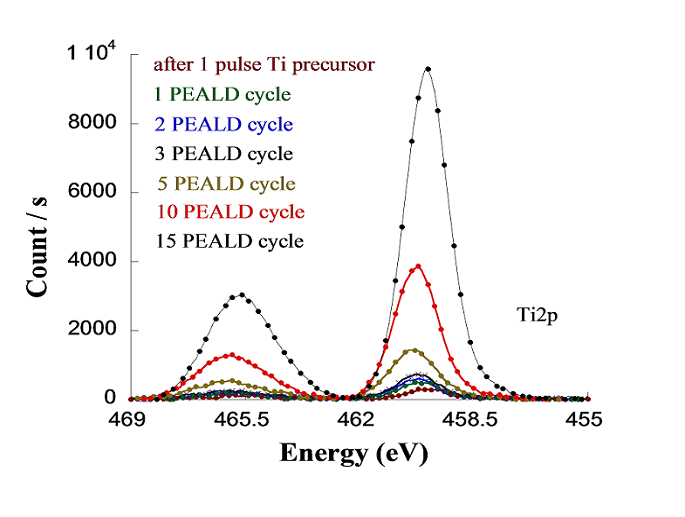

Selective deposition (ASD for Area Selective Deposition) processes are currently a very active topic of study in the microelectronic’s field. Indeed, this type of growth (bottom-up approach) allows to avoid problems of overlays or CD’s variability and mostly to lower costs compared to the classic top-down approaches requiring very complex developments when the dimensions are reduced: multipatterning, or Extreme UV. In this context a selective deposition process of TiO2 on TiN versus Si has been developed at lab [1]. This type of ASD deposition is based on alternating cycles of PEALD (Plasma Ehanced Atomic Layer Deposition) and phases of surface etching / passivation. In this scheme, these phases of passivation can avoid growth on intended areas for a certain number of cycles ALD. In order to understand and control the key steps in these processes during these successive deposit / engraving / passivation cycles, in-situ or quasi in-situ metrologies are valuable tools. They become mandatory when addressing surfaces presenting strong reactivity to air, as in this case here (TiN and Si). This concept of quasi in-situ analysis with mobile vacuum carrier [2] is one of the key facet of the IMPACT project and characterization platform, which has already been validated for many applications (various growth studies, reactive layers in plasma etching, surface functionalization,..) [3, 6]. Thus, after a synthetic description of the platform’s concept and setup the presentation will highlight this specific application for process development of PEALD selective deposition of TiO2 on TiN versus Si. In particular, the study will describe mechanisms involved for these selective growth cycles, and this at the level of the atomic layer, detailing each cycle from the first layers deposited.

Keynote Forum

Han-Yong Jeon

Inha University, South Korea

Keynote: Nanoclay application to geotextiles to improve adsorption function for removal of heavy metal and toxic components in waste landfill sites

Time : 10:40-11:15

Biography:

Han-Yong Jeon is a Geosynthetics/Technical Organic Materials Researcher and he was the 32nd President of Korean Fiber Society (2014~2015). He has published more than 881 proceedings in domestic and international conferences. He wrote 20 texts including 'Geosynthetics’ and also published 144 papers in domestic and international journals. He has won the awards of Marquis Who's Who-Science and Engineering in 2003~2018 and also, he got the 33rd Academy Award of Korean Fiber Society in 2006 and “Excellent Paper Award of 2012” by The Korean Federation of Science and Technology Societies.

Abstract:

- Nanoscience and Technology | Nano Medicine | Nanoparticles | Nano Electronics | Materials Chemistry | Nano Materials Synthesis and Characterisation

Chair

Sidorenko Anatolie

Institute of Electronic Engineering and Nanotechnologies, Moldova

Co-Chair

Myung Chul Chang

Kunsan National University, South Korea

Session Introduction

Bonamali Pal

Thapar Institute of Engineering and Technology, India

Title: Greener and selective synthesis of various aromatic amines by TiO2 nanocatalyst under light irradiation

Biography:

Abstract:

Yoshitaka Okada

The University of Tokyo, Japan

Title: Optimizing the structure of quantum dot Intermediate-band solar cells

Biography:

Abstract:

Biography:

Abstract:

Mirko Černák

Masaryk University, Czech Republic

Title: Fast low-temperature plasma calcination of ceramic nanofibres

Biography:

Abstract:

Van Kerckhove Gunther

OCSiAl Europe Sarl, Luxembourg

Title: Tuball â„¢ single wall carbon nanotubes: Health, safety & environmental issues

Time : 16:10-16:30

Biography:

Abstract:

Elisabetta Travaglia

Consiglio Nazionale delle Ricerche, Italy